Exploring the Latest Trends in Knife Sharpening Technology

The Evolution of Knife Sharpening Technology

Knife sharpening has come a long way from the traditional whetstones and manual methods. As culinary arts and cooking have evolved, so has the technology to keep knives razor-sharp. Today, modern knife sharpening techniques combine age-old practices with cutting-edge innovations, offering enthusiasts and professionals alike a plethora of options to maintain their blades.

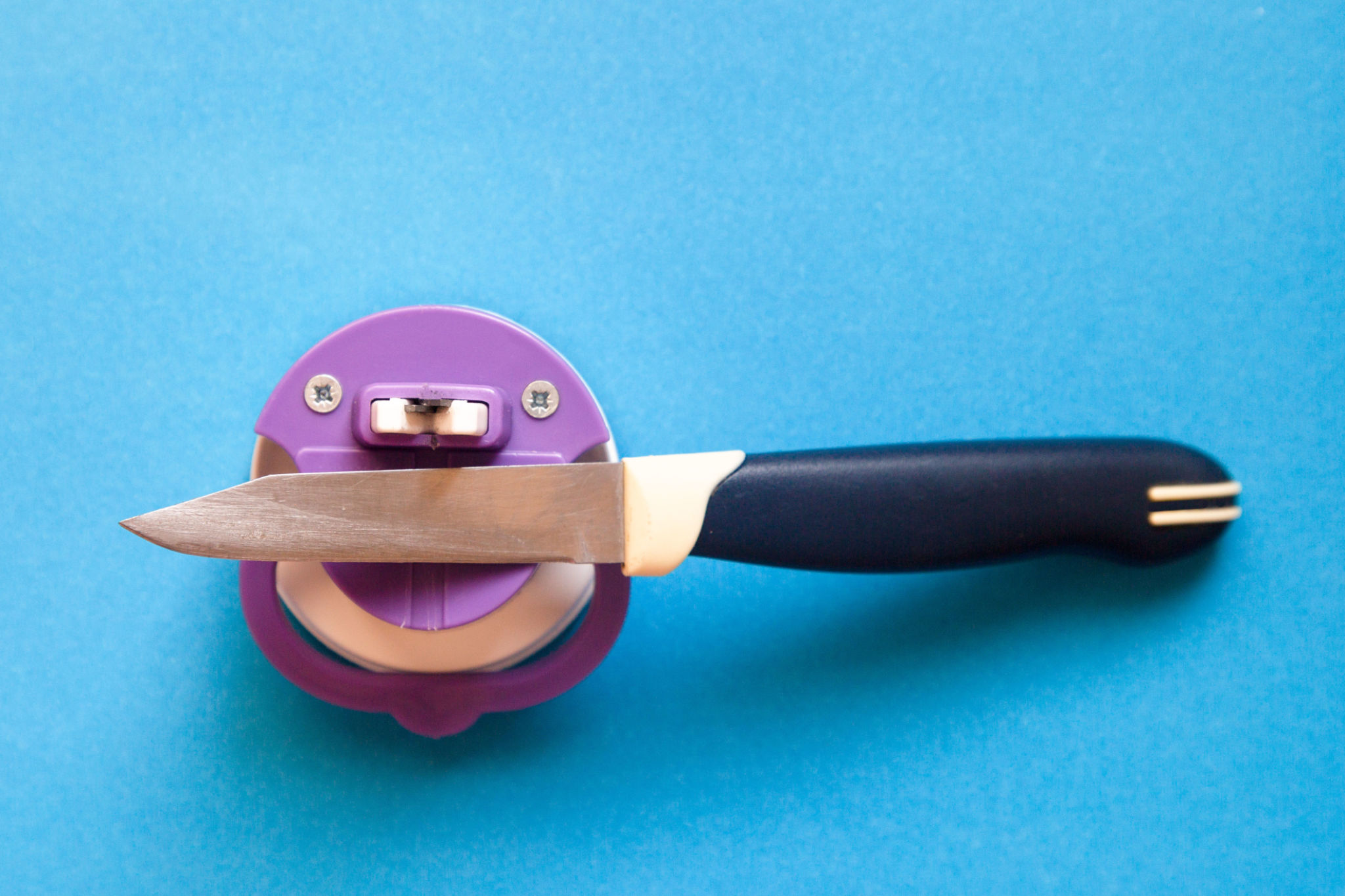

Electric Knife Sharpeners: Convenience Meets Precision

One of the most significant advancements in knife sharpening technology is the advent of electric sharpeners. These devices offer a blend of speed and accuracy, making them a popular choice for home cooks and professional chefs. With multiple stages for sharpening, honing, and polishing, they ensure that knives achieve a keen edge without much effort.

Electric sharpeners often come with preset angles, which are crucial for maintaining the blade's integrity. This feature eliminates the guesswork involved in manual sharpening and ensures consistent results every time. However, it's essential to select a model that matches the type of knives you own for optimal performance.

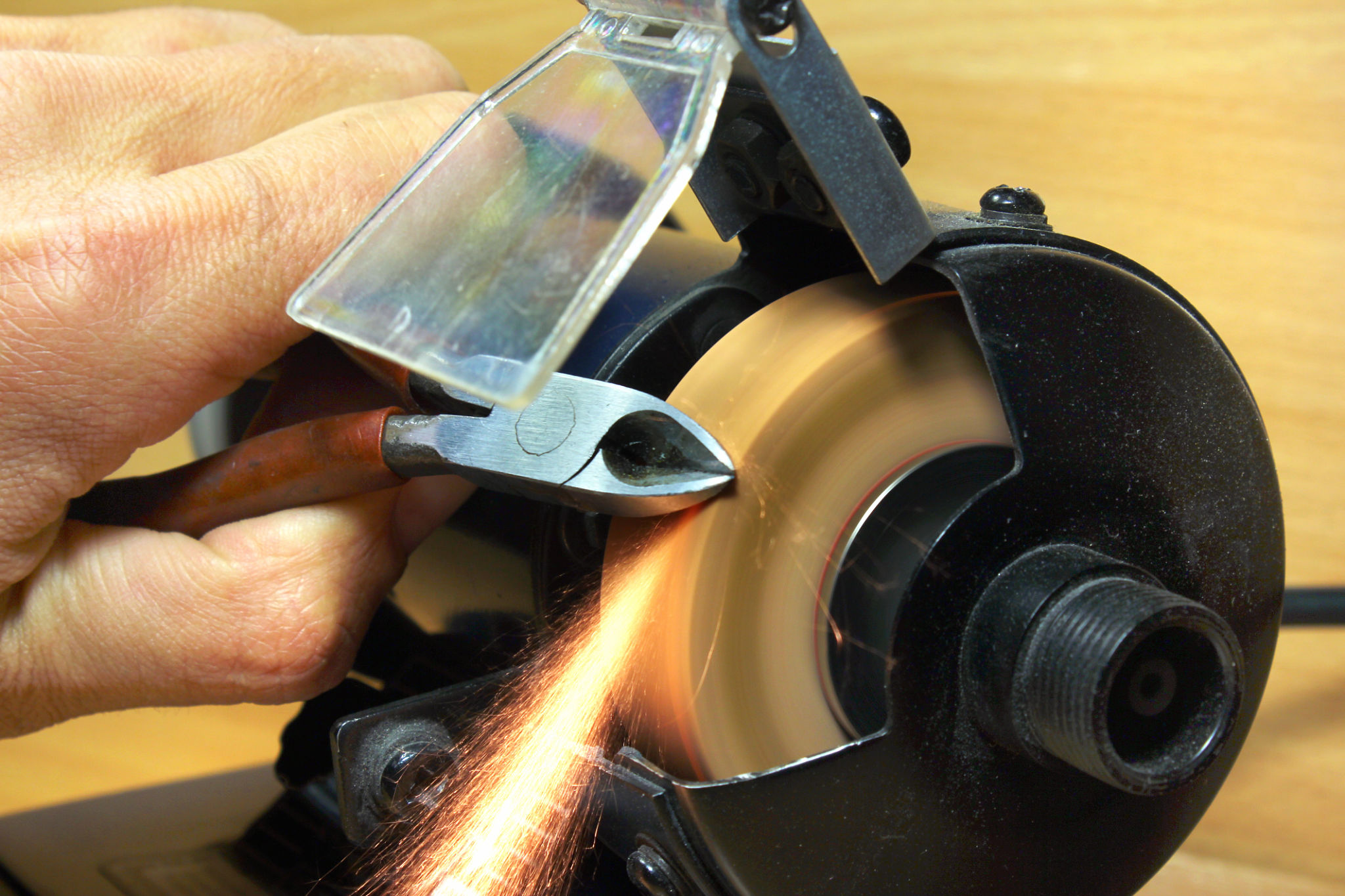

Water-Cooled Systems: Preserving Blade Temper

For those who are serious about maintaining their knives, water-cooled sharpening systems provide an excellent solution. These systems use water to cool the blade during the sharpening process, preventing overheating and protecting the blade's temper. This is particularly important for high-quality knives, as excessive heat can damage the steel.

Water-cooled systems are typically used by professionals who require precision sharpening. They offer adjustable speeds and angles, allowing for customization based on the specific requirements of each knife. While they are more expensive than electric sharpeners, the investment is worthwhile for those who prioritize blade care.

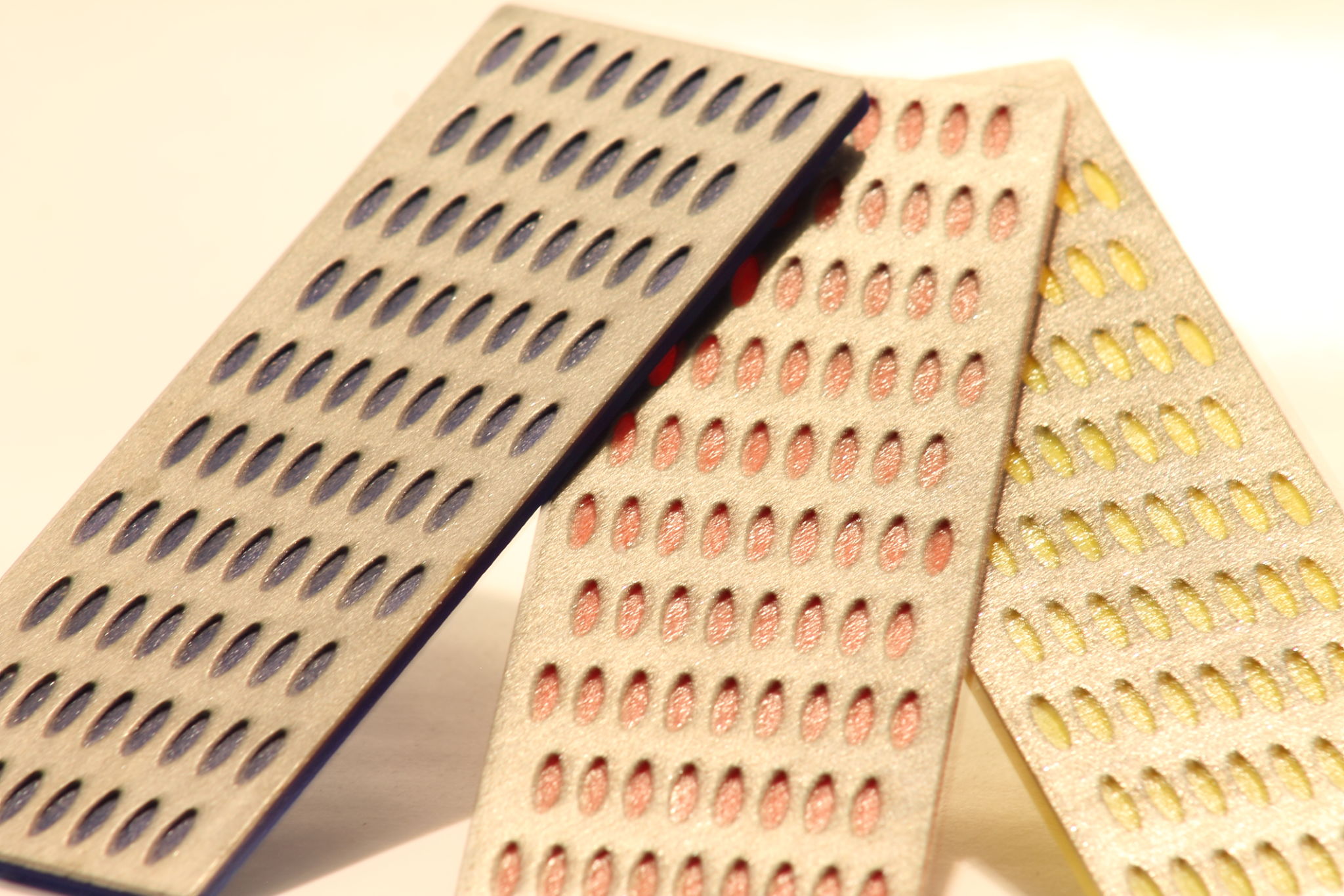

Diamond Abrasives: Cutting Edge Technology

Diamond abrasives have revolutionized the knife sharpening industry by providing one of the hardest and most durable surfaces for honing blades. These abrasives are embedded in steel or resin to create sharpening surfaces that effectively grind away dull edges while maintaining longevity.

Diamond sharpeners are available in various forms, including rods, stones, and electric models. They are especially beneficial for those dealing with extremely hard steels or ceramic knives, which traditional abrasives might struggle with. The efficiency of diamond abrasives makes them a preferred choice for those seeking quick and effective sharpening solutions.

Guided Sharpening Systems: Achieving Perfect Angles

For enthusiasts who enjoy a hands-on approach to knife maintenance, guided sharpening systems offer a great balance between manual and automated methods. These systems use clamps and guides to maintain a consistent angle while sharpening, ensuring precision without requiring extensive skill or experience.

Guided systems are versatile and can accommodate various blade types and sizes. They are perfect for hobbyists who want to refine their technique while enjoying the art of sharpening. The ability to adjust angles and pressure provides an opportunity to learn the nuances of blade maintenance.

Smart Technology: The Future of Knife Sharpening

The integration of smart technology into knife sharpening is an exciting development on the horizon. Concepts such as IoT-enabled sharpeners that can adjust settings based on user preferences or blade analysis are being explored. These devices aim to further simplify the process while delivering professional-level results.

As these technologies develop, they promise to make knife maintenance more accessible and efficient for everyone. Whether for personal use or professional kitchens, embracing these innovations will undoubtedly enhance our culinary experiences by keeping our tools in peak condition.